No mistake made twice: positive trajectory continues for safety

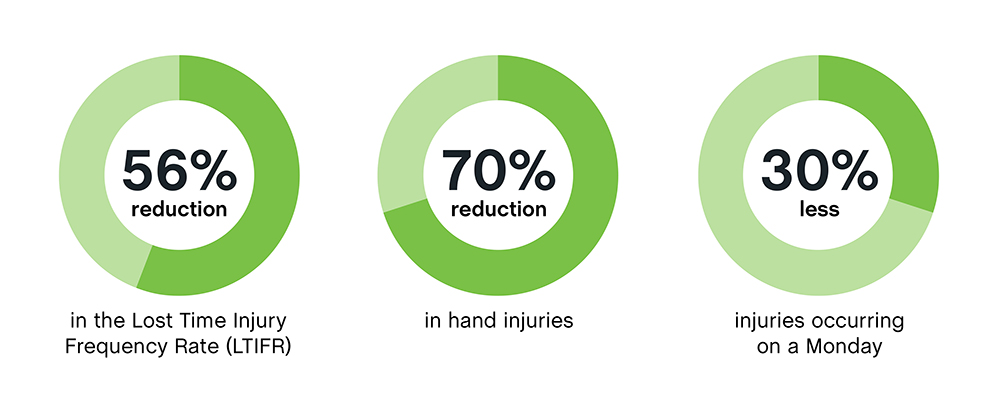

Buildcorp has done a lot of talking in recent months about the changes to our safety management including smarter data analysis, simpler processes and a strategic risk focus. Proudly these changes have resulted in a record three year result (2014-2016) which shows a 56% reduction in lost time due to injuries (LTIFR), including a 70% reduction in hand injuries and 30% less injuries occurring on Monday.

These figures further support that our commitment to continual learning has transformed the way we view and manage safety on our sites, making a big impact on our people and teams. Buildcorp recently asked our widely experienced Safety Coordinator Sean Gemmell (SG) to explain how the changes to safety management are affecting how we work at the coalface.

Sean, how did you develop your career in safety?

SG: From the start of my career I worked on sites in general labourer roles, including as a leading hand, and crane and forklift operator. Then, in my beginnings at Buildcorp six years ago, I had the opportunity to include more safety coordination in my responsibilities and this evolved into a full-time role, working on Buildcorp’s game-changing hospital redevelopment for the SAN in Sydney.

I have always liked to work in roles that help people. I’m also a self-confessed perfectionist who works hard to avoid making the same mistake twice. My previous experience as a labourer meant I was already aware of the risks and understood how subcontractors work. This set me up to better help people and challenge any pre-existing trade norms where I know tasks can be done more effectively and safely.

How have Buildcorp’s changes to safety and risk management affected what you do?

SG: The simpler processes and strategic focus on higher risk tasks has meant we spend more time on the things that matter and have a big impact. For example, our Safe Work Method Statement (SWMS) review process is now a lot more effective. Instead of focussing on generalist tick-boxes and formatting in a process that also relied on the trade knowledge of the assessing Foreman or Supervisor, the SWMS now asks more specific questions about the activities related to high risk tasks. This allows people to ask the right questions to assess safety management even without detailed knowledge of the subcontractor’s trade or task in question.

From your own experiences, what are some of the biggest factors contributing to Buildcorp’s successful reduction of LTIFR?

SG: Our weekly Toolbox Talks educate and work with the subcontractors, and this goes a long way to sustaining a more lasting change in site safety. It’s important to find an effective way of getting through to people about why safe work practices matter using both the crucial ‘people factor’ and the practicalities of cost savings and a better work environment.

At a broader level, Buildcorp’s sharing of safety data on a real-time dashboard has had one of the bigger, more visible impacts on the way our teams talk about and prioritise safety. The visual dashboard is a great way to communicate to the team about what we’re measuring and what’s important to know, and they take it on board instantly. There is also healthy competition amongst the teams as they all want to score well and do the best, but I reinforce to everyone to “stay focused on what’s happening directly in front of them and the results will come”.

It’s also what we do with this data that has had an impact. The recent statistics that show a huge 70% reduction in hand injuries and 30% less injuries occurring on Monday have come about because we identified trends in the data and then changed something in our people, plant or processes to help address this. The changes here included mandatory Monday morning safety walks and mandatory wearing of gloves and glasses on site.

And how have these changes affected the teams you work with?

SG: Well over a year ago my role changed from a dedicated safety administrator for one project to now managing safety across a number of projects. The safety system changes have definitely impacted where I focus my time and how I interact with these project teams. A lot of what I do is now about educating and influencing a range of stakeholders to further invest in safety.

Encouragingly, the project teams have implemented the high risk work changes so well, that when I turn up to site, the high risk works are under control and well managed. It’s great to attend a site and see excavation or civil works running smoothly and safely, and all I may need to focus the team on is low risk tasks such as sweeping the roads after works to ensure they’re clean and obstacle-free. This is a sign that the teams are prioritising their safety management in the right place and it’s my job to keep Project Managers focused on some of the smaller details of a safe and well run site at the same time. Our teams are often juggling many priorities, risks and deadlines, so I also need to be conscious of giving them the right support and time to respond to any audit findings.

Ultimately, you could say that the safety system changes have made my job both easier and harder; I now focus more of my time on convincing people to do these less critical things which can sometimes be more challenging!

Finally, what’s your favourite part of the job?

SG: When you’re asking subcontractors to implement a new safety process they haven’t done before, it’s great to come back and see that they’ve taken the advice on board. It can even be simple things like ensuring all their workers’ tools are tied to their wrists or the machinery when they’re working at height on scissor lifts. This isn’t always a common practice and using a basic rope is often fine, but I had one contractor go out and purchase the best professional lanyards they could find and proudly showed me these in use the next time I visited the site, which I really appreciated.